(BLOG UPDATED 3rd August 2018)

News

Preliminary user manuals can be downloaded from these links:

VXP1 Handbook Rev 1.0

VXP1-OS Hand Book Rev1.3

Back Story

A few years ago I designed and built a Eurorack interface for my Moog Voyager. I built it in a week to take to the Brighton Modular meet to see if there was any interest in such a module.

I have a Moog VX-351 which is a perfectly lovely bit of kit but I wanted something that had 3.5mm minijacks to make it easier to use with my Eurorack and Roland 100m modulars. The module I built was a simple breakout panel that had one jack per signal available on the Voyager's Accessory Port (a 25 pin D connector). Most signals were wired straight through but one or two included active electronics to provide scaling to give a more useful 5V range, in particular Keyboard Pitch had a scaling amplifier and a trimmer to set it exactly to 1V/octave. LEDs with driver circuits were also added to the LFO and the two gate signals. |

| Prototype Voyager Output Expander |

Most modular users don't have a Voyager (and sadly it's now out of production) so I didn't get too much interest at the Brighton meet but I did get some interest on Twitter and Muffwiggler and in particular from one wiggler whose frequent enquiries about its development has spurred me on to develop it. It has been very slow going due to a number of reasons (not all connected to the module itself, the real world has a way of changing one's focus!).

Output Adaptor Retrofit

One reason for procrastination was due to an error in Moog's design of the Voyager's Accessory Port which was not suitably buffered; which means that when a cable is connected to the port some of the signals become unstable and oscillate. Moog's remedy for this was to use a small adaptor board that has to be retrofitted inside the Voyager between the main circuit board and the Accessory Port's ribbon cable (this just affects backlit types, not the Old School version).The Output Adaptor is a small circuit board that adds a 330 Ohm resistor in series with many of the signals; here is a link to an installation guide. The 330 Ohm resistance is enough to isolate the capacitance of the extra cable length which maintains amplifier stability (ED Note: If you want to understand about amplifier stability then this series of 5 short videos by Analogue Devices is the perfect intro, in particular video 4 which describes this problem nicely. Ideal for anyone designing with op-amps).

As you will see from the installation guide that fitting the adaptor is a bit much for some people to take on and I didn't want to encourage inexperienced Voyager owners to open up their expensive synth and potentially damage it or harm themselves (there is an AC mains hazard around the power inlet if you don't disconnect from the mains). Unfortunately there is no other solution other than to use an Output Adaptor (like that supplied with the VX-351) so fit it if you are confident or get a music shop tech to fit it for you. You might already have one fitted if your Voyager has been used with the Moog VX-351. I tried to find a source of Moog Output Adaptors but alas no joy so I designed one from scratch; problem solved! Here it is:

Smaller, Better

Another reason for delay is that I increased the scope of what the VXP1 can do; I didn't want this to be a Eurorack rip-off of the VX-351. Rather than just a simple breakout panel it now handles each signal with active electronics as follows:- All signals are filtered, buffered and have the necessary gain and drive to give more Eurorack-friendly output levels.

- The smooth and step Sample and Hold outputs are replaced by just one output and a variable control to give an adjustable slew to Sample and Hold.

- There are more LFO waveforms: ramp, saw and 10V clock.

- There are more noise options: white, red and random pulses.

- The panel is narrower than the first prototype: 16HP down to 14HP.

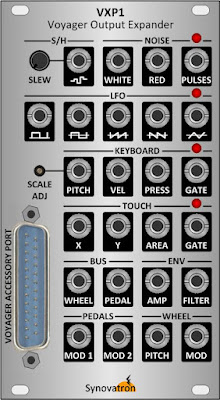

Here is the panel design:

For Old School Voyagers which don't have a touch panel the VXP1-OS has repurposed the redundant TOUCH sockets to become a 3-input gate combiner.

VXP1 Module, Cable and Adaptor | VXP1-OS Front Panel